During the time of perforated sheet production, the industry is welcoming stage wise strong inspection that results in the greater output. As the industry is having highly skilled and well-experienced professionals that are engaged in the production of these metal sheets effectively with no errors and lacking in quality.

The inspection is performed from the first stage that is buying of raw substances to the last stage of packaging and delivering of the item. This gives them surety of offering a commendable quality of service. If talking about the testing, yes, the producers are giving importance to testing to check product quality before it finally gets shipped. The testing performed is a mechanical test, chemical test, hardness test, positive material identification test, intergranular corrosion test, flattening and flaring test, pitting resistance test etc.

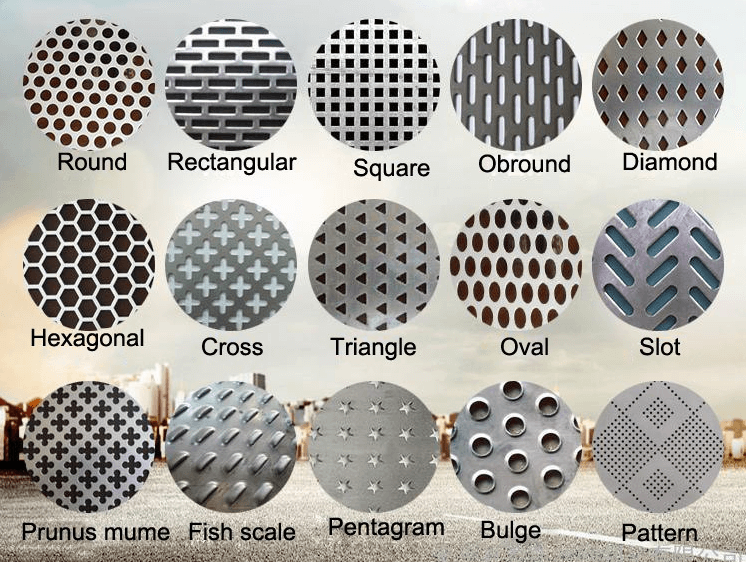

Perforated sheet is having wider use in industries like acoustics and sound control, food processing, automotive, architecture and construction, furniture and fabrication. These perforated metal sheets are available for the buyers in various forms like a square, round, triangle, rectangular holed for perfectly meeting the application requirements with no hassle.

Specifications

Surface : 2B, BA, HL, Brush, NO.1, NO.4, 8K, SB, etc

Thickness : 0.3-15mm

Size (Feet X Feet) : 8 x 4 - 8 x 3

Width : 1000mm~2000mm or customized

Length : 1000mm~6000mm or customized

Application : Bridge, Shipbuilding, roofing, Car, etc

Surface Finish : Polished

Quality Control : 0.4 mm to 5.0 mm

Standard sheet sizes : 1000mm*2000mm, 1250mm*2500mm, 1219mm*2438mm, 1500mm*3000mm We can produce other standard as customized

|